As a cardboard box manufacturer, we provide customers with high-quality, customized, and reliable cardboard box solutions. We have first-class domestic cardboard box design, manufacturing, and transportation capabilities, which can meet the different needs of different customers.

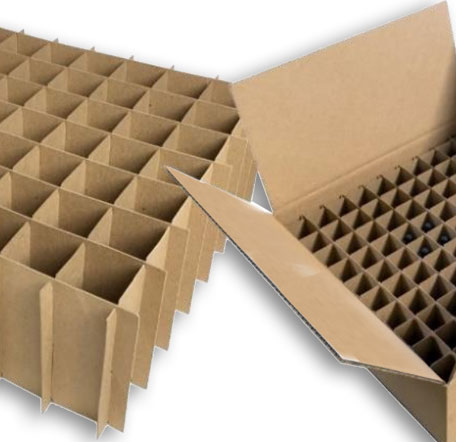

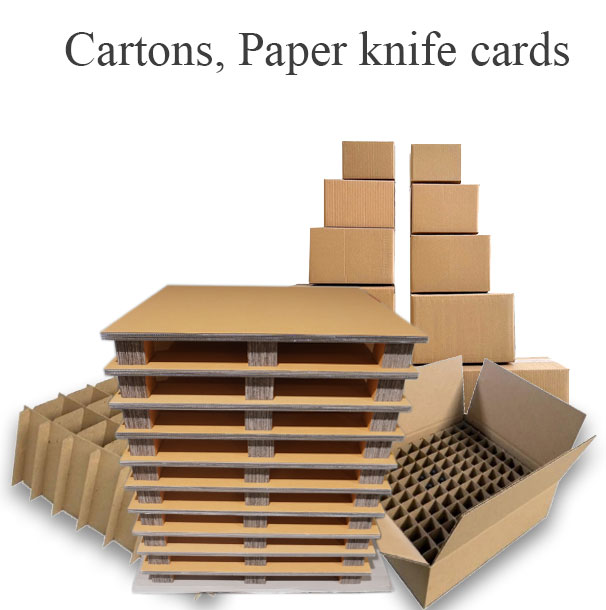

Our products come in various styles of cardboard boxes, as well as partitions, paper pads, and knife clips, which can meet the needs of different customers. From small portable cardboard boxes to large cardboard boxes, we have a professional production team to provide every customer with the highest quality products. At the same time, we can also customize special cardboard boxes according to customer requirements to meet their various needs. Make you worry free and effortless, and make your products safer and more environmentally friendly.

Our products come in various styles of cardboard boxes, as well as partitions, paper pads, and knife clips, which can meet the needs of different customers. From small portable cardboard boxes to large cardboard boxes, we have a professional production team to provide every customer with the highest quality products. At the same time, we can also customize special cardboard boxes according to customer requirements to meet their various needs. Make you worry free and effortless, and make your products safer and more environmentally friendly.

VISION

We lives up to our promises. Will try o develop paper boxes, packaging, produce good quality products, reasonable prices, impressive service. On time delivery in order to provide customers with good quality products from us.

MISSION

1.Expanding the potential of excellent service in carton packaging to support the diverse

needs of customers.2.Develop good planning and management for efficiency and effectiveness of operations.

3. Continuously develop personnel’s attitudes, skills and work strategies. To upgrade products and services.

Classification of corrugated cardboard

According to different combinations, corrugated cardboard can be divided into the following four types:

The corrugated cardboard boxes are mainly divided into A type, B type, C type, and E type.

A-shaped corrugations have good elasticity, large height and spacing, good shock absorption, and are suitable for products that are fragile and have high requirements for impact and collision;

B-shaped corrugated board is suitable for making product packaging that is rigid and does not require shock absorption and protection performance, such as canned goods, small packaged food, small hardware, etc;

C-shaped corrugations combine the characteristics of both AB corrugations and have sufficient rigidity and shock absorption performance;

E-shaped corrugated boxes can have a flat surface, better rigidity, and are suitable for high-quality printing, while saving transportation and storage space.

The corrugated cardboard boxes are mainly divided into A type, B type, C type, and E type.

A-shaped corrugations have good elasticity, large height and spacing, good shock absorption, and are suitable for products that are fragile and have high requirements for impact and collision;

B-shaped corrugated board is suitable for making product packaging that is rigid and does not require shock absorption and protection performance, such as canned goods, small packaged food, small hardware, etc;

C-shaped corrugations combine the characteristics of both AB corrugations and have sufficient rigidity and shock absorption performance;

E-shaped corrugated boxes can have a flat surface, better rigidity, and are suitable for high-quality printing, while saving transportation and storage space.

Box type classification

The box type of corrugated cardboard boxes can be combined according to different types and layers, such as single corrugated boxes (three layer cardboard boxes), double corrugated boxes (five layer cardboard boxes), three corrugated boxes (seven layer cardboard boxes), etc.

Classification of corrugated structures. The corrugated structure of corrugated cardboard boxes is mainly divided into single corrugated boxes, double corrugated boxes, and three-layer corrugated boxes. A single corrugated box is composed of one layer of corrugated cardboard and two layers of cardboard, a double corrugated box is composed of two layers of corrugated cardboard and three layers of cardboard, and a three layer corrugated box is composed of three layers of corrugated cardboard and four layers of cardboard.

Classification of corrugated structures. The corrugated structure of corrugated cardboard boxes is mainly divided into single corrugated boxes, double corrugated boxes, and three-layer corrugated boxes. A single corrugated box is composed of one layer of corrugated cardboard and two layers of cardboard, a double corrugated box is composed of two layers of corrugated cardboard and three layers of cardboard, and a three layer corrugated box is composed of three layers of corrugated cardboard and four layers of cardboard.

General classification of corrugated paper

1. Paper can be divided into K paper, A paper, B paper, and C paper in order of quality

A. According to grade (GB), it can be divided into A-grade paper, B-grade paper, a small amount of C-grade paper, and corrugated paper.

B. According to color, it can be divided into white card color and cow card color.

C. According to different weights, corrugated paper can be divided into 100G, 125G, 140G, and 180G; There are various types of base paper available, including 150G, 160G, 170G, 175G, 200G, 250G, 260G, 280G, etc.

A. According to grade (GB), it can be divided into A-grade paper, B-grade paper, a small amount of C-grade paper, and corrugated paper.

B. According to color, it can be divided into white card color and cow card color.

C. According to different weights, corrugated paper can be divided into 100G, 125G, 140G, and 180G; There are various types of base paper available, including 150G, 160G, 170G, 175G, 200G, 250G, 260G, 280G, etc.